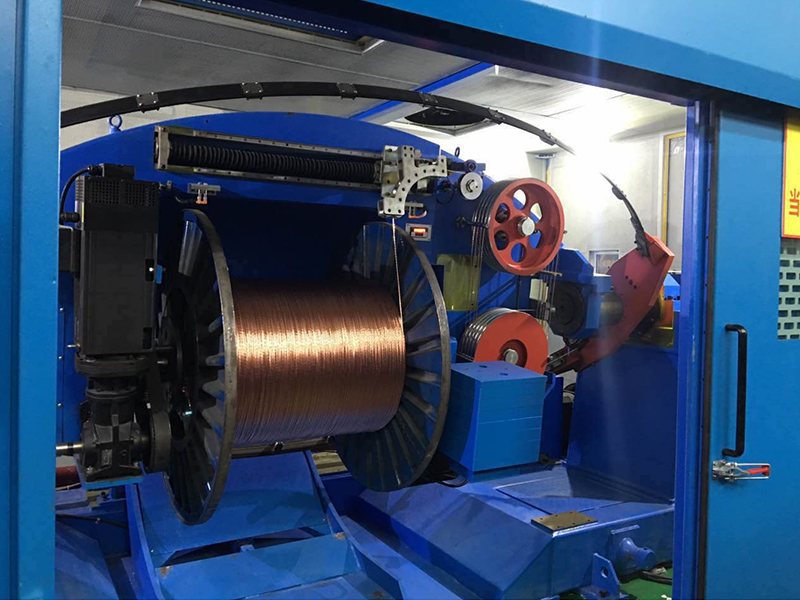

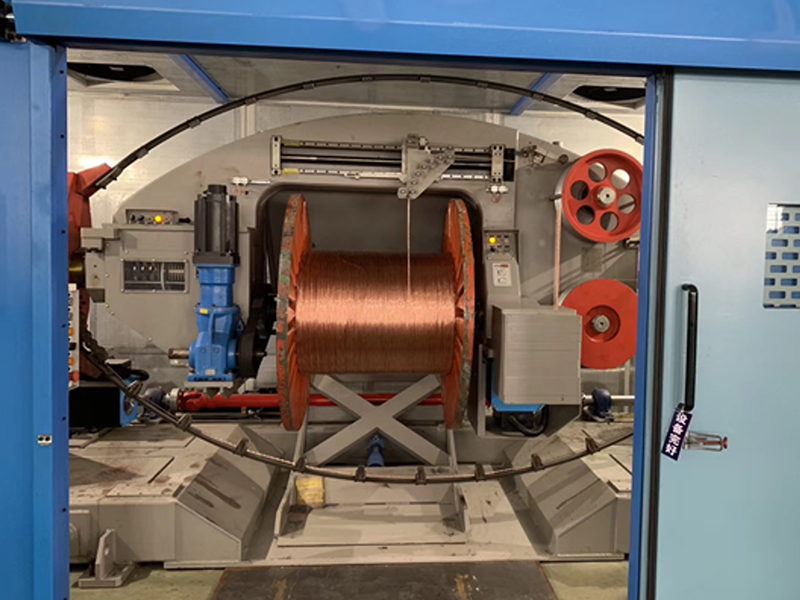

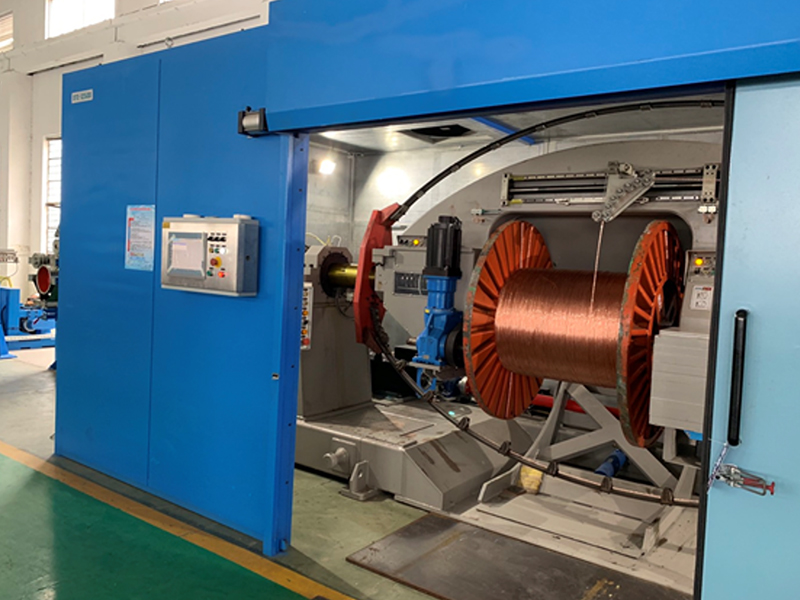

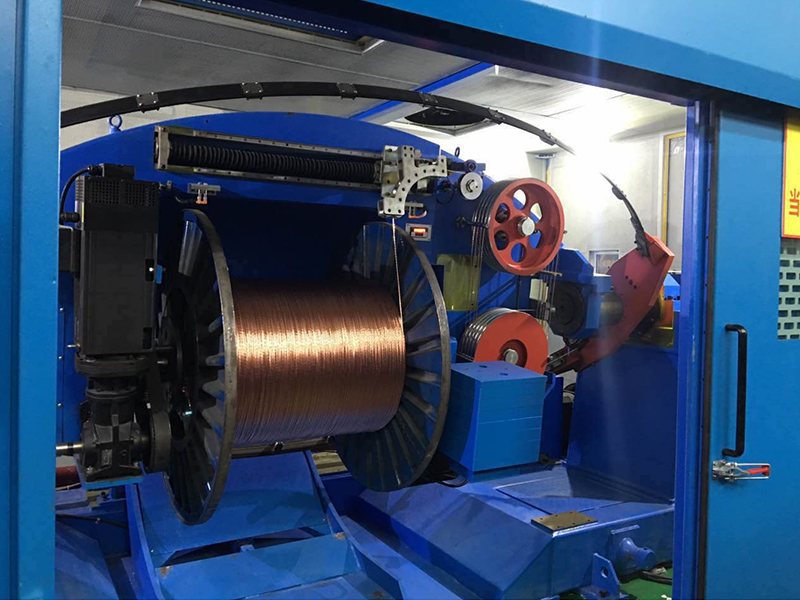

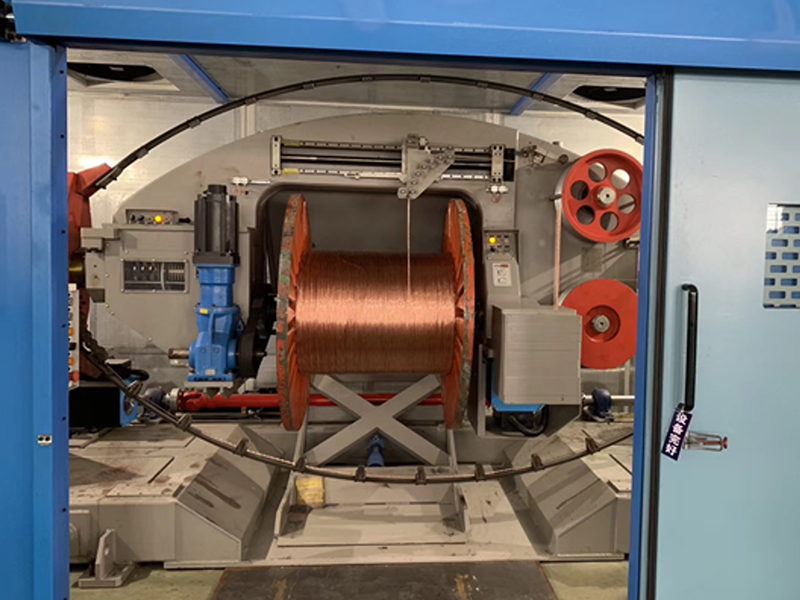

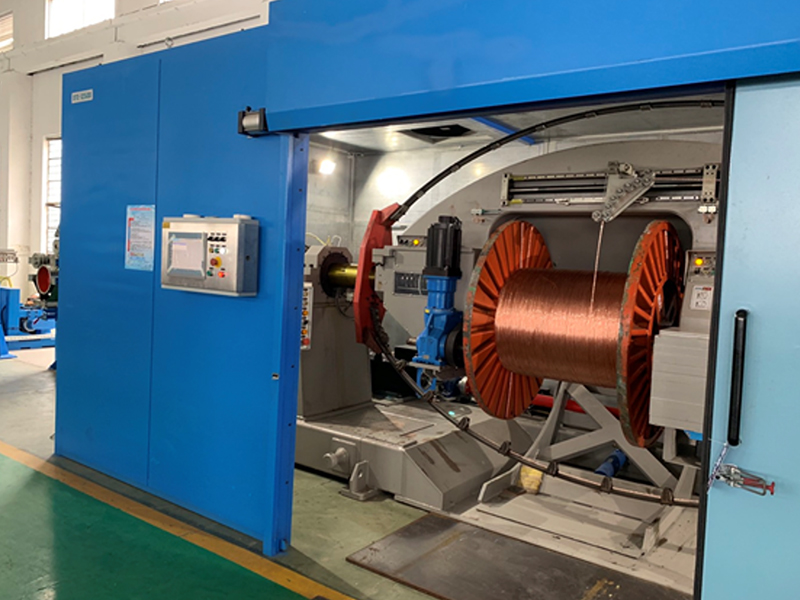

Double bow technique is adopted

Wireless signal transmission

Excavation free foundation and installation

The space is very small

Ultra short cable channel

Reliable slip ring system

Hydraulic up and down discharger

Automatic lubrication system

Automatic bearing temperature sensing system

Servo motor energy saving 20%

Advanced aerodynamic design

Servo motor and control system

NSK bearing, high tensile strength

Installation of smart meter in control cabinet

Introduction of application

This equipment is dedicated to twist Aluminum and Copper round compress conductor. This project contains external rotation pressure die structure, and provide the required traction used for compress conductor, when the conductor compress, the take-up part of bundling machine will obtain, and have a special line way to reduce torque between rotating traction wheel and take-up bobbin, can ensure that there is a good round conductor.

Main parameter

| Type | Ф1250mm | Ф1600mm |

| Wire diameter of wire inlet | Φ1.0mm-3.0mm /7cores(Copper wire ) /50mm2 Φ1.5mm-3.5mm/ 7 Cores (AL wire)/70mm2 Φ2.0mm-6.5mm/2-4 cores (2-4 cores 1.0mm2-10.0mm2) |

Φ1.5mm-4.8mm /7cores(Copper wire ) /50mm2 Φ1.5mm-4.8mm /37cores(Copper wire ) /150mm2 Φ1.5mm-5.0mm/ 7 Cores (AL wire)/70mm2 Φ1.5mm-5.0mm/ 7 Cores (AL wire)/240mm2 Φ2.0mm-6.5mm/2-4 cores (2-4 cores 1.0mm2-10.0mm2 |

| Conductor section area of stranding | 5.5-50mm2 (Copper conductor) 10.0-70mm2 (AL conductor) |

16-150mm2 (Copper conductor) 37heads pay off 16.0-240mm2 (AL conductor) 37 heads pay off |

| Lay range(Copper and Aluminum) | 40-350mm. Thumb wheel type setting automatic calculation and adjustment. | 50-600mm. Thumb wheel type setting automatic calculation and adjustment. |

| Wire diameter of stranding | ||

| Stranding section (flexible strands) | 3.5-70mm2 | 10-70mm2 |

| Stranding section (1 + 6) | 3.5-50mm2 | 10-50mm2 |

| Compacted copper | 3.5-50mm2 | 16-150mm2 (with 37 heads pay off) |

| Compacted aluminum | 3.5-70mm2 | 16-240mm2 (with 37 heads pay off) |

| Maximum line speed | 150m/min | |

| Maximum compression pressure coefficient | 13% | |

| Direction of twisting | S.Z. (Left and right twisting direction can be selected) | |

| Speed of rotation body | 800 RPM/MAX. (1600 Twist), normal working speed:600RPM(1200 twist) | 450 RPM/MAX. (900 Twist), normal working speed:300RPM(600 twist) |

| Power | ||

| Main frame | 55KW servo Motor | 90KW DC Motor+ digital control |

| Capstan | 30KW servo Motor | 55KW DC Motor +digital control |

| Spool tension | 7.5KW servo Motor | 18.5KW DC Motor+ digital control |

| Traverse unit | 0.75KW servo Motor | 1.5KW servo Motor |

| Rotation die stand | 0.75KW servo Motor | 2.2KW servo Motor |

| Spool drum size | Max 1250mm | Max 1600mm |

| Spool load capacity | Max 5000KG | Max 8000KG |

| Power source | 380V, 50Hz(or depend on customer’s requirement) | |

| Drum loading and unloading | Type: Motor shaftless type. Bobbin load /unload: by electric lifting platform control |

|

| Low noise design | Main machine noise is insulated by safety cover, noise below -80db. | |

| Brake | Adopt pneumatic brake | |

| Control | PLC system control | |