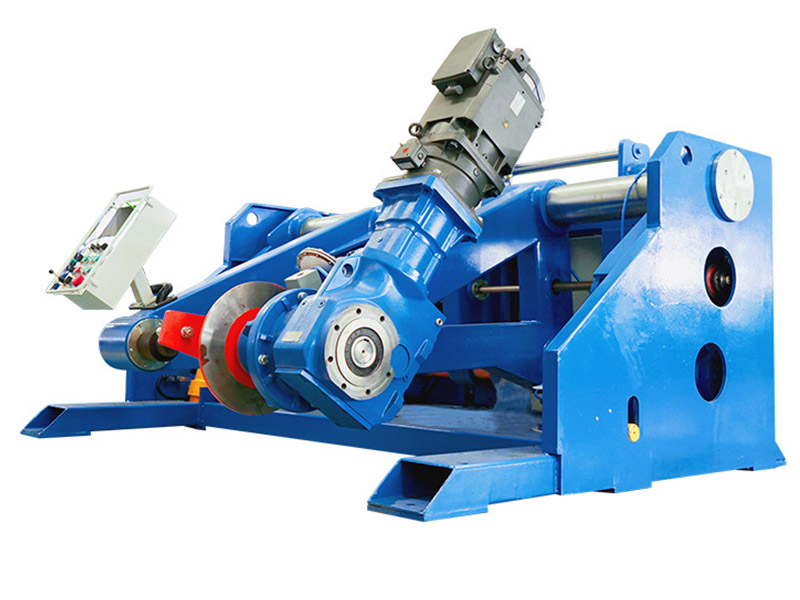

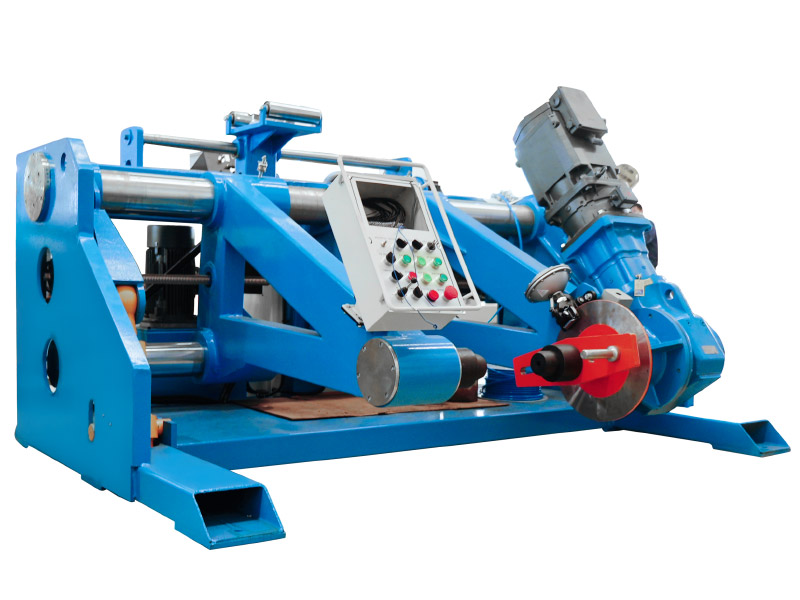

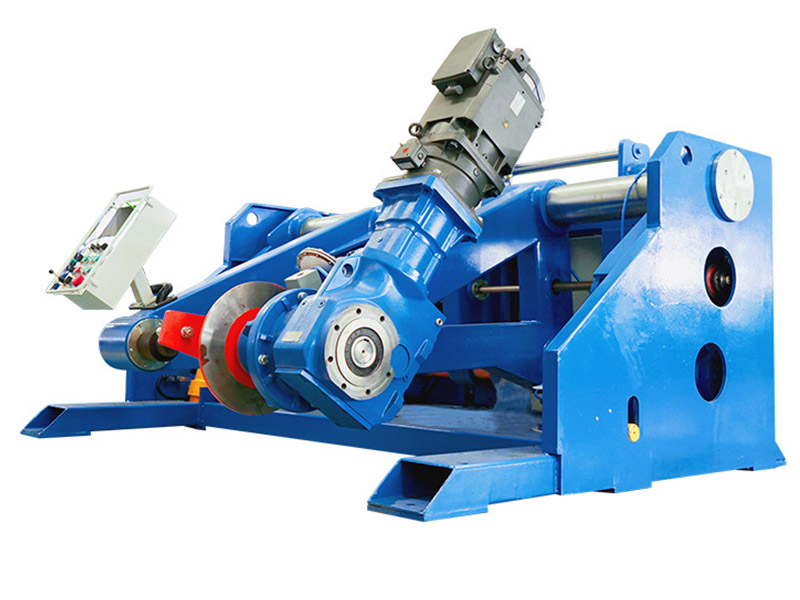

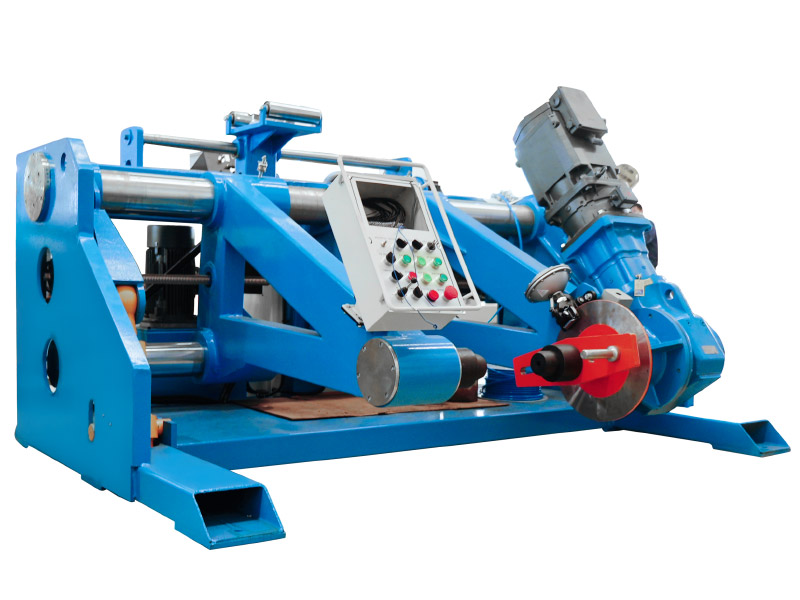

Mainly for stranding, extruding and irradiated lines.

Bobbin supported in cantilever being the bobbin lifting done through hydraulic cylinders and the pintles closing done through a motor and a worm drive. It adopts hydraulic swing arm double casting structure, hydraulic lifting and lead screw clamping;

High precision cable traversing done through a worm drive with servo motor;

Designed for processes which require high speed and big bobbin sizes;

HMI+PLC control system for speed synchronization with the line.

| Model | CHYD-1250 | CHYD-1600 | CHYD-2000 |

| Applicable wire –coil specification [mm] | Φ630-1250 | Φ800-1600 | Φ1000-Φ2000 |

| Applicable wire-coil width [mm] | 475-950 | 600-1180 | 750-1500 |

| Applicable wire diameter [mm] | Φ5-30 | Φ6-40 | Φ8-60 |

| Load capacity [kg] | 2000 | 4000 | 6000 |

| Take-up speed [mm/min] | 200 | 100 | 100 |

| Motor power / Pay off [kw] | 7.5 | 11 | 11 |

| Motor power / take up &traverse [kw](Servo screw motor) | 1 | 1 | 1 |

| Motor power / Clamping [kw] | 0.4 | 0.4 | 0.4 |

| Bobbin Lift | Hydraulic | Hydraulic | Hydraulic |

| Electrical Control &HMI | SIMEN200PLC+7” | SIMEN200PLC+7” | SIMEN200PLC+7” |