Standardization

Since our establishment, Shineworld Group makes standardized production a primary rule, promoting mass and systematic manufacturing of cable manufacturing equipment.

With the long-standing standardization and refinement of the production process, Shineworld Group continuously upgrades and evolves our machinery. The meticulous attitude leads to the quality of the equipment and provides you with a consistent operating experience from start to finish.

Since our establishment, Shineworld Group makes standardized production a primary rule, promoting mass and systematic manufacturing of cable manufacturing equipment.

By inviting national scientific researchers and material experts to design and experiment, Shineworld Group successfully developed the first PE lagging( for cable drum protection) and novel materials in China.

With over 18 years of experience and handling over 40 complete solutions per year, our team excels in professionalism.

With the support and guidance of Shanghai Cable Design Institute, we break through the tradition and insist on the integration of innovation and practicality in our machines and processes.

In the machining center, all key components are bored in one piece to ensure concentricity, making them fit the equipment more closely and run more smoothly, effectively extending the service life of the parts and equipment so as to reduce maintenance costs for you.

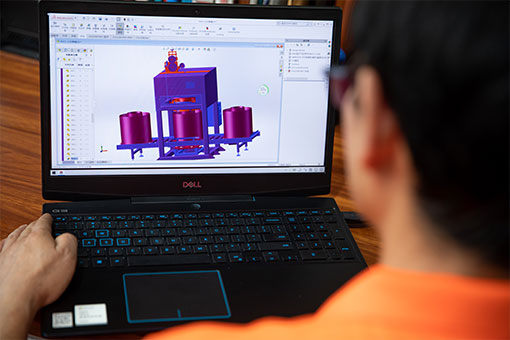

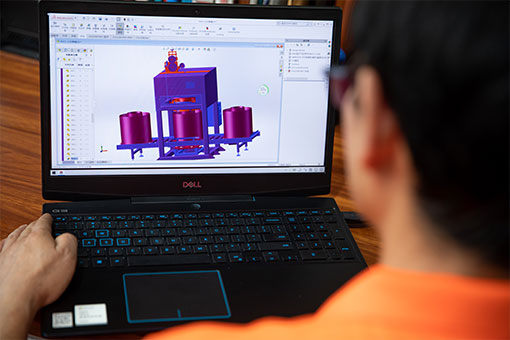

At Shineworld Group, intellectual modernization is particularly essential, as our machining centers are managed and monitored by integrated CNC control, allowing parts to be machined in one-shot, guaranteeing accuracy and efficiency, reducing lead times from the source, and thus delivering equipment on time.

Within the celebrity product extrusion line, we have adopted a high-efficiency extrusion screw design that can increase the extrusion volume by 30%, further increasing the output. It also reduces production waste for an environmentally sustainable result and reduces your management costs.

Our production plant is equipped with a large number of welding, cutting and machining machines. By increasing the professionalism of our equipment, we make large-scale standardized production more efficient.

Meticulous division of labor, skilled operations and solid technical support ensure that our equipment is delivered within schedule.

Well over 18 years of production experience, combined with countless global projects, set our production team apart from its peers. Under the leadership and management of this elite team, the high-quality production of equipment becomes easy and disciplined.

Starting from the consultation, every step of your order is solid and smooth. Budget control, design analysis, technical support, professional procurement, logistics, and transportation to after-sales service. We are always ready to assist you in getting on-time delivery and earlier profitability, which is essential.

Room 1603, No.950 Dalian Road, Yangpu District, Shanghai

+86-18317122980

18800241639@shineworldgroup.com

No.101-10, Kechuang Road, Changdang Lake Science and Technology Venture Park, Jintan, Changzhou, China

+86-18317122986

WhatsApp us

*Please upload only jpg, png, pdf, dxf, dwg files within 10MB.

*We respect your confidentiality and all information are protected.

*We respect your confidentiality and all information are protected.