Welding Results is perfect.

Pulling force test: constant to the joints.

The resistance test: Resistance value is not greater than that of the original wire.

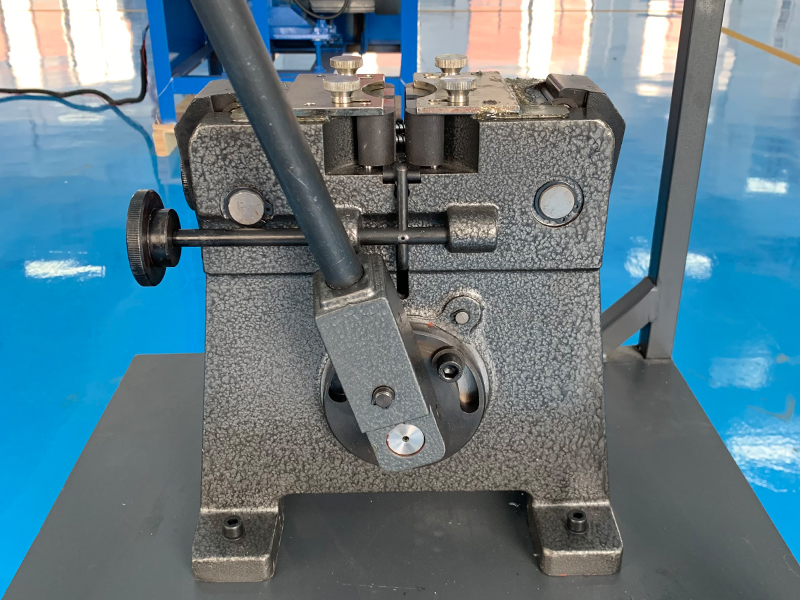

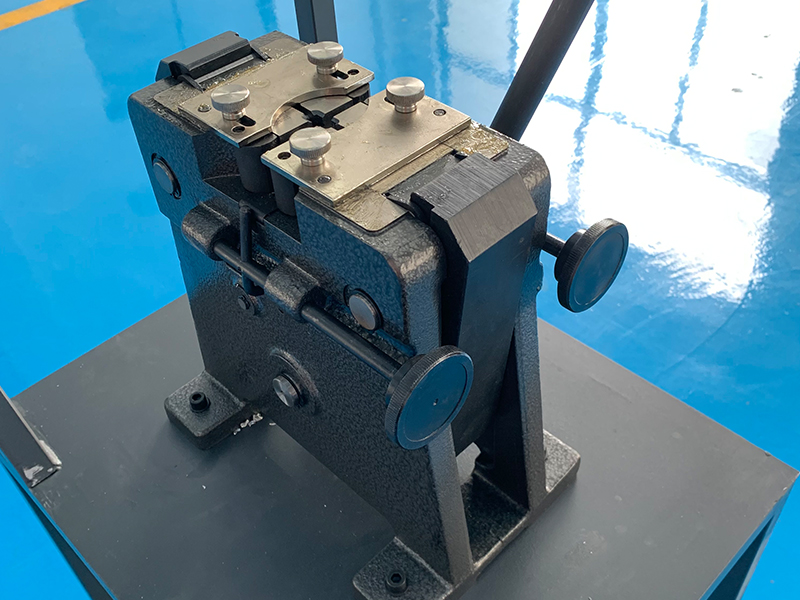

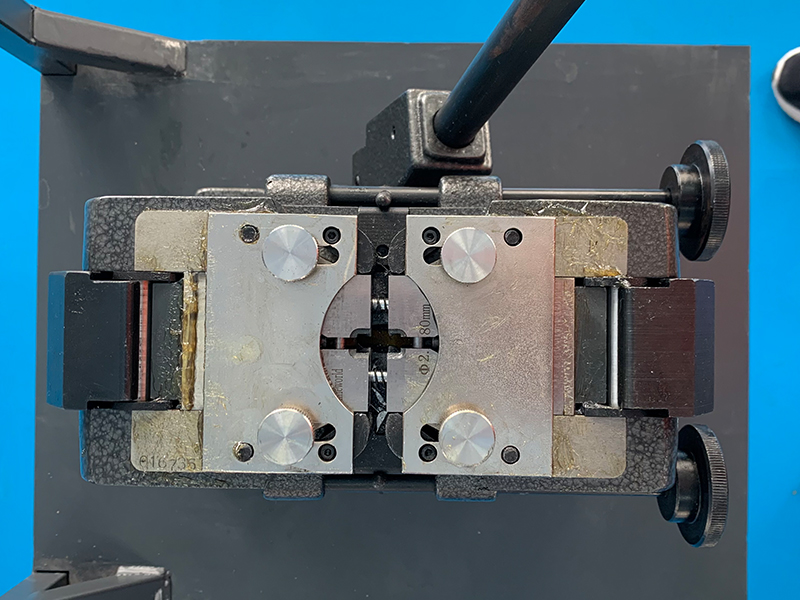

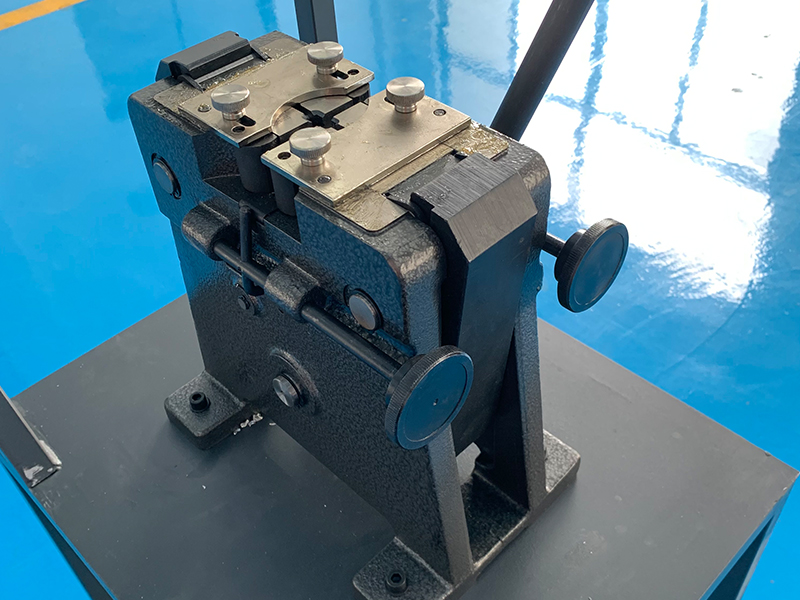

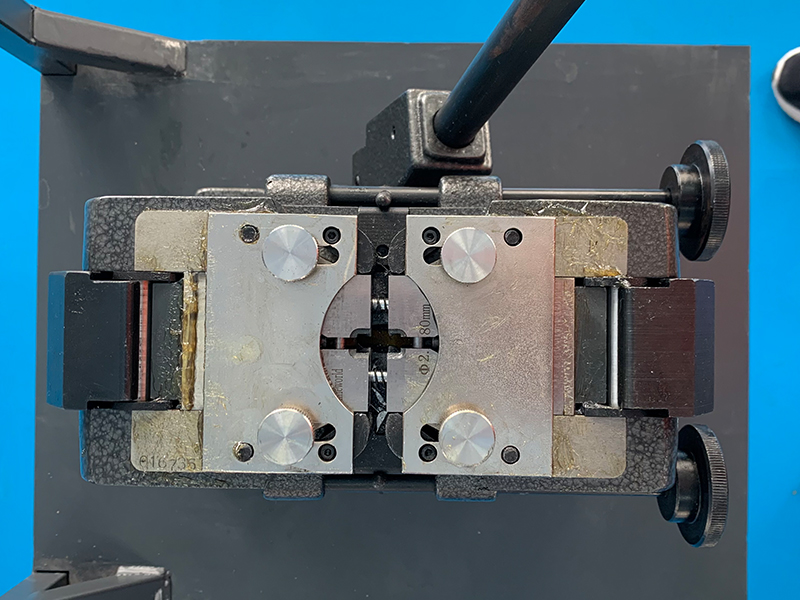

Changes of wire diameter: In order to meet the user’s need for welding the wires of various materials our company can provide the cold welding dies having various kind if inner grooves for users.

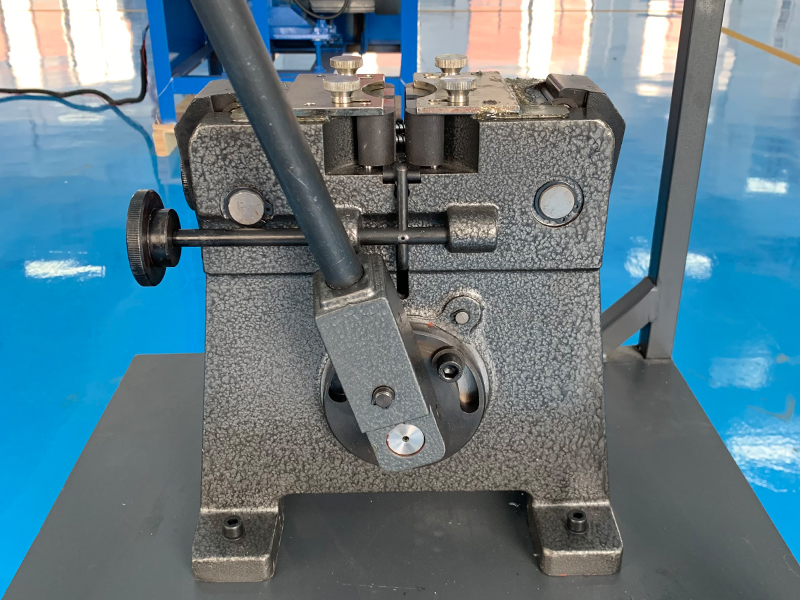

Without power supply, safe and reliable, simple operation and welding, after welding the resistance of the material material elongation and related physical and chemical indicators won’t change.

How to choose the model

| Item | Model | Copper wire size | Aluminum wire size | Dimension | N.W | Die |

| (mm) | (mm) | (mm) | ||||

| J1 Portable | SWM-J1 | Φ0.10~0.50 | Φ0.10~0.50 | 160x50x160 | 1Kg | J1 |

| J1 | SWMJ1T | Φ0.10~0.55 | Φ0.10~0.60 | 260×90×220 | 3Kg | J1 |

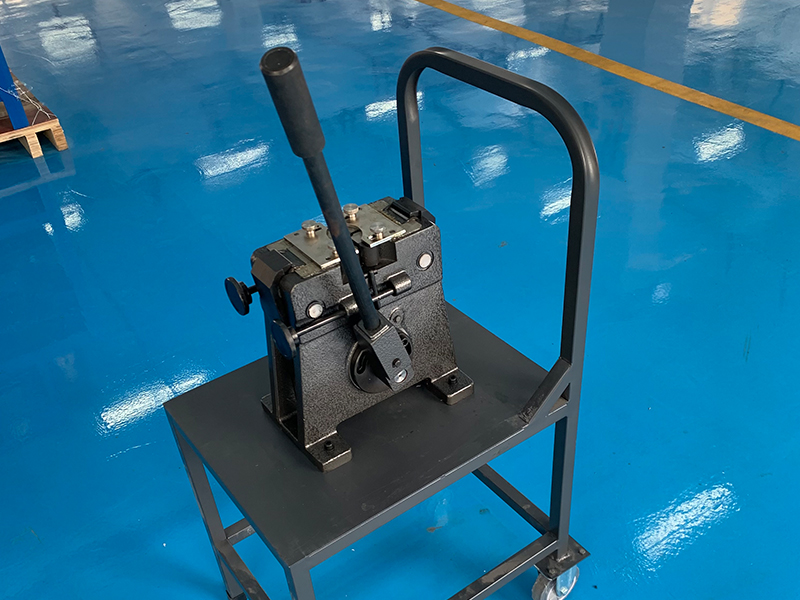

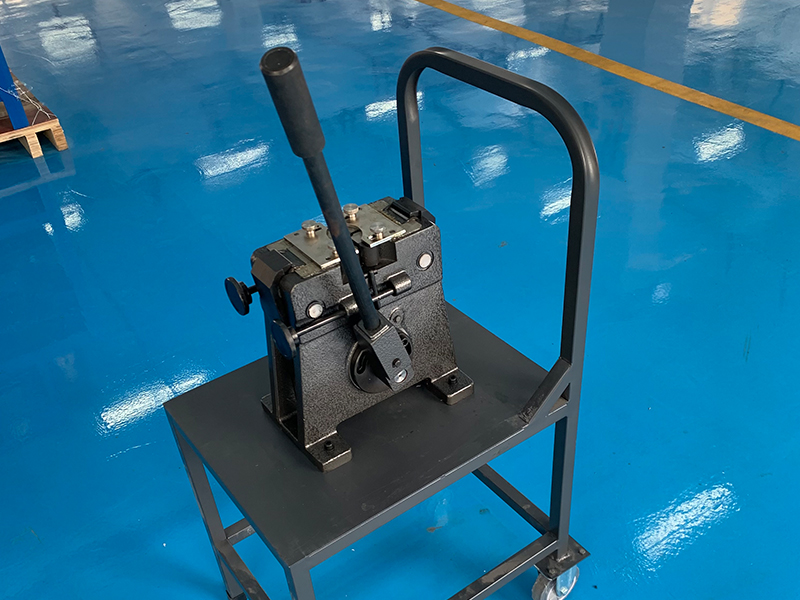

| J2 | SWM-2T | Φ0.30-Φ1.20 | Φ0.30-Φ1.40 | 220x130x200 | 9.5Kg | J2 |

| J3 | SWM-3T | Φ1.00-Φ3.25 | Φ1.00-Φ5.00 | 300x180x300 | 36Kg | J3 |

| J4TY | SWM-4T | Φ1.00-Φ4.00 | Φ1.00-Φ6.00 | 550x550x920 | 130Kg | J4 |

| J5TY | SWM-J5TY | Φ4.00-Φ8.00 | Φ4.00- 14.00 | 1190x570x1100 | 650Kg |

Specification

| Type | SWJ1T | SWJ2T | SWJ3T | SWJ4T |

| Product use | Copper, aluminum, gold, silver, nickel, platinum, zinc, tin, tantalum, niobium and other non-ferrous metals and their alloy wires’ cold welding. | |||

| Welding Size | Cu: 0.1 mm-0.55 mm, Al: 0.1mm-0.60 mm, | Cu: Φ0.30-Φ1.20mm Al: Φ0.30-Φ1.40mm, | Cu: Φ1.00-Φ3.25mm Al: Φ1.00-Φ5.00mm, | Cu: Φ1.00-Φ4.00mm Al: Φ1.00-Φ6.00mm |

| Products material | The body made for Precision casting steel | |||

| Advantage | Without power supply, safe and reliable, simple operation and welding, after welding the resistance of the material material elongation and related physical and chemical indicators won’t change. | |||

| Dimensions | L×W×H 260×90×220mm | L×W×H 220x130x200mm | L×W×H 300*180*300mm | L×W×H 550x550x920mm |

| G.W | 3.0Kgs | 9.5Kgs | 36 Kgs | 130 Kgs |

| Dies | J1 | J2 | J3 | J4 |