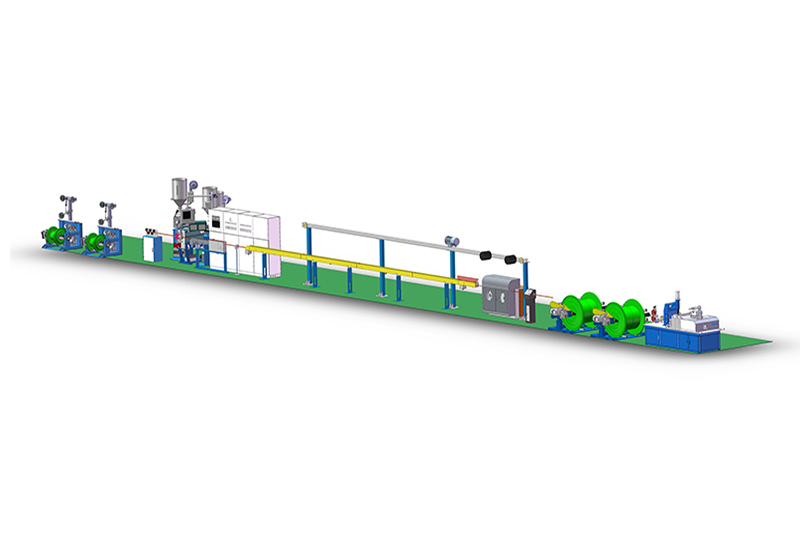

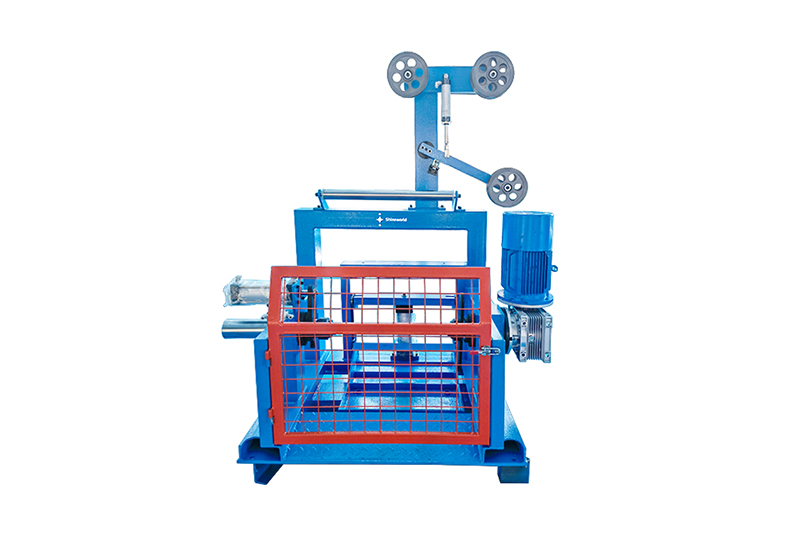

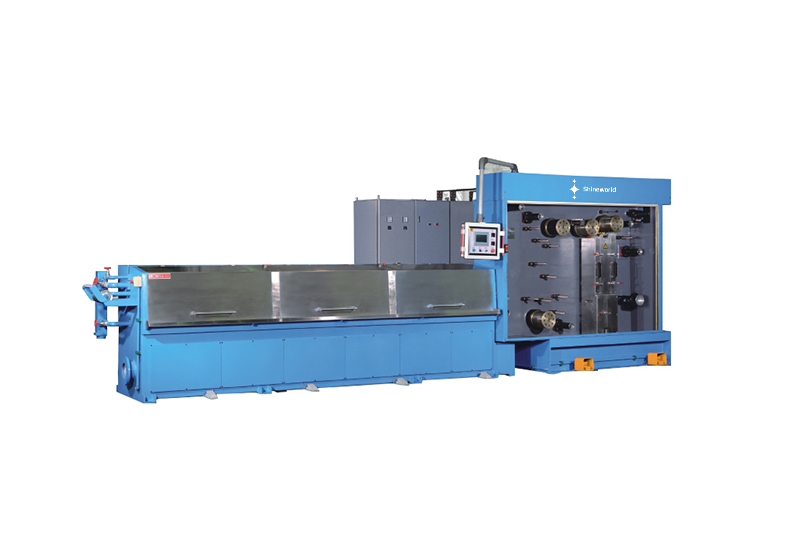

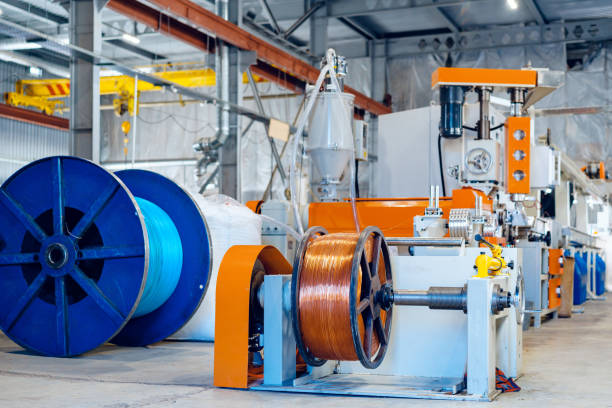

Inclusive Solutions Steps That Save Your Worries

We are committed to providing comprehensive and professional plant solutions to investors worldwide. We build your plant quickly and professionally, with complete technical support from start to finish, eliminating the hassle of installation and commissioning for you.